What is extrusion of polycarbonate?

Perhaps you have witnessed this procedure previously, particularly in industrial settings, but you were unaware of its nature.

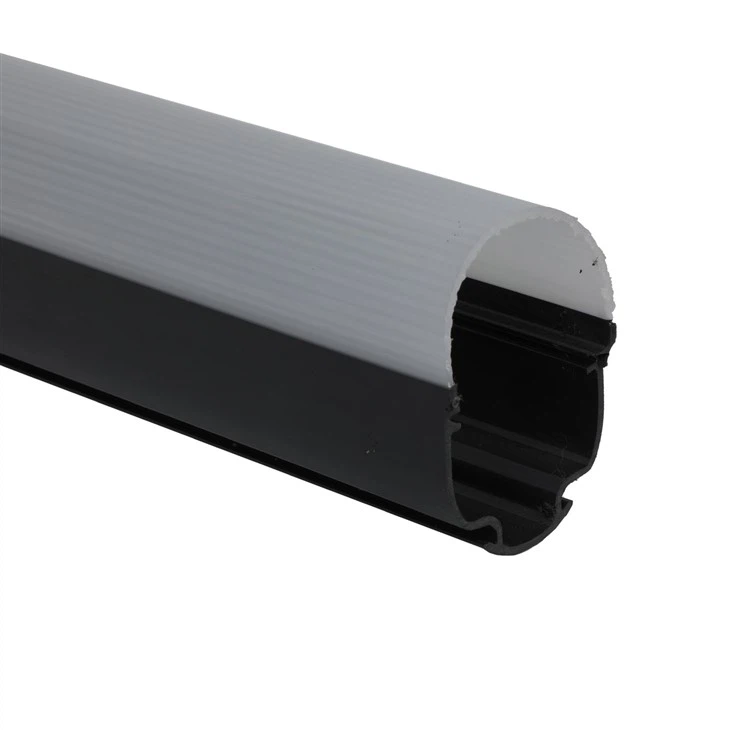

In any case, polycarbonate extrusion is a process for mass production that involves melting raw plastic components and shaping them into continuous shapes.

The preferred technique for creating a variety of shapes for usage in domestic and industrial product applications is polycarbonate extrusion.

To get the greatest results, this is a somewhat sophisticated process that calls for some of the best equipment and expertise.

With your foundational knowledge of polycarbonate extrusion now established, let’s examine a few of its benefits.

Benefits of extrusion of polycarbonate

As a matter of fact, polycarbonate is a solid polymer possessing remarkable qualities including durability to high temperatures and impacts.

As such, it gives you the ideal option for utilizing this particular technology, allowing you to create goods that are appropriate for a variety of uses.

I hope we can look at a few of this technology’s benefits and how it helps with work in general in this area.

But the truth is that extrusion of polycarbonate offers a practical, affordable, and effective way to make plastic goods.

Among the benefits are the following:

a) It produces continuous product shapes quickly and effectively.

The technology of polycarbonate light diffuser extrusion is essential for processing continuous product forms fast and effectively.

As you can see, this is significant since it makes it possible to produce goods with consistent shapes.

Better yet, creating these goods in bulk makes it much more important since it allows you to attain and sustain consistency.

Extrusion is therefore the best option if you’re searching for a productive way to process polycarbonate and create continuously formed items.

b) Generally less expensive than alternative polycarbonate processing techniques

As you can see, there are several applications for polycarbonate materials in the production of diverse goods.

Since most of these technologies require a variety of equipment and procedures, they are rather costly.

Conversely, extrusion is less expensive because it doesn’t require sophisticated equipment or skilled labor.

As a result, you’ll see that extrusion is more effective but also somewhat less expensive than other technologies.

c) Permit you to acquire items with complex shapes, differing thicknesses, and surfaces

Presently, as far as the upsides of this cycle, this is another critical benefit worth examining.

Polycarbonate expulsion permits you to make items with various complex shapes.

In the mean time, you can likewise utilize it to create items with various surfaces and thicknesses.

This is essential since you understand that in numerous plastic handling advancements, it is challenging to track down an item that can give you this multitude of qualities.

This, as a rule, permits you to openly concoct probably the best plastic items reasonable for a large number of utilizations.

d) Simple to join with numerous added substances to further develop item execution

The ability to combine this method with other additives to raise the product’s quality is still another important benefit.

To put it another way, squeezing makes it simple to combine different components, which enhances the functionality of the finished product.

For instance, you can decide to add chemicals to improve the anti-fog or anti-scratch performance during the extrusion process.

Additional characteristics of the material are its resistance to fire, longevity, and less friction or static electricity.

This is important, by the way, because it enables you to get the ideal outcomes in terms of the caliber of your final output.

Here, “product quality” refers to a few fundamental qualities that set a product apart and help it become the best option for a certain use.

e) Permit simple alteration following extrusion

It can be said that this is the only method in plastic manufacturing that allows for the manipulation of product performance once the process is finished.

In this instance, as the plastic resin exits the extruder, it is still extremely hot.

As a result, you can carry out related post-extrusion procedures in accordance with your unique requirements.

Most significantly, though, is that this procedure lets you alter the product in any way that suits your needs.

As you can see, this technique has a lot of legitimate benefits.

However, we also have to acknowledge that it has certain disadvantages that are important to bring out.

Extrusion of polycarbonate also have disadvantages

a) Product restrictions

In most cases, the properties of polycarbonate extrusion molding process often limit the products it can manufacture.

You will notice that in many cases, there are alternatives that often require investment in different types of extrusion machinery.

b) The possibility of size differences

This is also another common drawback of this special polycarbonate manufacturing process.

When plastic leaves the extruder, it often expands frequently.

At this stage of the process, the expansion of polycarbonate is referred to as die expansion.

Now, due to the fact that expansion is caused by different factors in the process, predicting the accuracy of expansion has become challenging.

It is the unpredictability of material expansion that makes you accept significant deviations from product tolerances or dimensions.

Of course, you also need to understand that we have several methods to limit such issues.

FAQ:

1.What types of plastics do you commonly use?

The commonly used materials for our plastic extrusion are PVC,ABS,PC,PMMA,PP,PC/ABS,ASA etc.

2. Does your plastic extrusion product meet environmental requirements?

Our plastic materials meet environmental requirements and are recyclable, with minimal impact on environmental pollution.

3. What is the price basis for your quotation?

Our product quotation is determined based on material price, shape difficulty, order quantity and product requirements,so the larger the promised order quantity, the more discounts we will offer. Generally speaking, the simpler the product, the lower the requirements, or the larger the order quantity, there will be a discount.

4.What are the application scenarios of your extrusion product?

Our polycarbonate light diffuser extrusion are widely used in fields such as building materials, transportation, electronics, daily necessities, medical devices, etc.

Get a polycarbonate light diffuser extrusion quote Today!

At Custom Profiles, we are devoted to dealing with all of our clients. We need to ensure your expelled plastic requirements are all met with 100 percent fulfillment. We utilize state of the art innovation to make the specific sort of expelled item you want.

Hot Tags: polycarbonate light diffuser extrusion, China, suppliers, manufacturers, factory, customized, buy, made in China