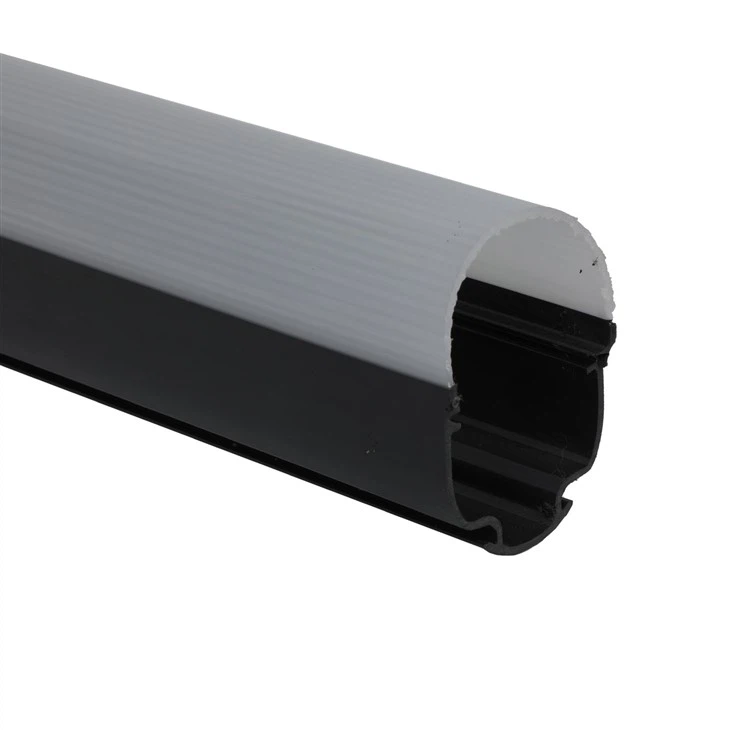

Material : PC lupilon E-2000 UR

Color : Origin

Size : 50.5*50*2MM

Thickness : 2m

Weight : 120g/meter

Length : Within 6 meter

Price : $6.8/product weight per kg(Prices may change at any time due to exchange rates, raw material prices and order quantity)

MOQ : 300kgs

Polycarbonate is a high-performance, tough, amorphous, and transparent thermoplastic polymer, whose organic functional groups are connected together by carbonate groups (- O – (C=O) – O -) and have unique performance for polycarbonate led diffuser plastic.

Amorphous materials mean that they do not exhibit the ordered characteristics of crystalline solids. Typically, amorphous plastics exhibit a gradual softening trend (i.e., they have a wide range between their glass transition temperature and melting point), rather than exhibiting a sharp transition from solid to liquid, as in crystalline polymers.

Polycarbonate was first produced by H. from Bayer AG in Germany Dr. Schnell and D. from General Electric W Fox, prepared in 1953. PC comes in two types: sheet and round, making it very suitable for subtraction processing on milling machines or lathes. Colors are usually limited to transparent, white, and black. Parts processed with transparent materials usually require some post-processing to remove tool marks and restore the transparency of the material.

Polycarbonate (PC) is a type of polymer that contains carbonate groups in its molecular chains. According to the type of R group, it can be divided into aliphatic, aromatic, and alicyclic groups. Polycarbonate led diffuser plastic has high strength and high transparency, making it the fastest growing general-purpose engineering plastic among the five major engineering plastics.

Polycarbonate is a new material (advanced polymer material) industry strongly encouraged by the Chinese Mainland in recent years. It is an important basic material connecting the upstream petrochemical industry with the downstream consumer electronics, electronic engineering, large aircraft, high-speed rail, defense and military industry, aerospace, auto parts manufacturing, household appliances, polycarbonate led diffuser plastic, building panels, durable consumer goods, optical lenses, optical disc substrates, special protection and medical devices and other fields.

Analysis and prediction of global PC supply and demand

The global polycarbonate led diffuser plastic production capacity and demand are steadily increasing. In 2022, the world’s PC production capacity increased by 9.0% year-on-year, and production increased by 2.5% year-on-year; The average operating rate of the device is 70.3%. Northeast Asia has the largest proportion of PC production capacity in the world. The world’s PC production is mainly concentrated in Northeast Asia, Western Europe, and North America, accounting for 59.6%, 16.6%, and 11.8% of the world’s total production capacity, respectively.

In 2022, there are more than 30 major PC production enterprises in the world, and the top ten production enterprises account for 71.5% of the total production capacity. Among them, Covestro is the world’s largest production enterprise, accounting for 20.9% of the world’s total production capacity, with Saudi Aramco and Zhejiang Petrochemical ranking second and third respectively.

In the future, global polycarbonate led diffuser plastic will continue to steadily grow, with Asia being the main consumption growth point. At present, the PC market in developed countries in Europe and America is basically saturated, and the demand growth rate is slowing down. Asia will be the region with the largest demand for PC.

FAQ:

1.What types of plastics do you commonly use?

The commonly used materials for our plastic extrusion are PVC,ABS,PC,PMMA,PP,PC/ABS,ASA etc.

2. Does your plastic extrusion product meet environmental requirements?

Our plastic materials meet environmental requirements and are recyclable, with minimal impact on environmental pollution.

3. What is the price basis for your quotation?

Our product quotation is determined based on material price, shape difficulty, order quantity and product requirements,so the larger the promised order quantity, the more discounts we will offer. Generally speaking, the simpler the product, the lower the requirements, or the larger the order quantity, there will be a discount.

4.What are the application scenarios of your extrusion product?

Our extrusion products are widely used in fields such as building materials, transportation, electronics, daily necessities, medical devices, etc.

Get a polycarbonate led diffuser plastic quote Today!

At Custom Profiles, we are devoted to dealing with all of our clients. We need to ensure your expelled plastic requirements are all met with 100 percent fulfillment. We utilize state of the art innovation to make the specific sort of expelled item you want.

Hot Tags: polycarbonate led diffuser plastic, China, suppliers, manufacturers, factory, customized, buy, made in China