DFM design guide for plastic extrusion and extrusion parts

Sep 01, 2021

Leave a message

Process introduction

Extrusion molding is a molding processing method with many changes, high productivity, strong adaptability, wide application and the largest proportion in the field of plastic material processing.

Extrusion molding is to continuously shape the polymer melt or viscous fluid through a certain shape die under the extrusion action of the screw or plunger of the extruder. The resulting parts are continuous profiles with constant section shape.

Not all thermoplastics can be processed by extrusion.

Common base materials include hard materials and elastic materials.

Hard materials: PVC, PC, PETG, ABS, PP, hips, PMMA, LDPE, HDPE, POM, ASA, PA, as, EVA, PC + ABS, etc

Elastic materials: PVC, TPU, TPE, Poe, TPR, TPV, TPEE, etc

As with the design of injection molded parts and aluminum extruded parts, uniform wall thickness is very important.

If the wall thickness of the plastic extrusion part is uneven, some parts are thick and some parts are thin, which makes the flow velocity of the plastic extruded in the die uneven, resulting in different cooling rates and eventually deformation of the part.

If the deformation needs to be controlled, additional cooling processes need to be added to reduce the efficiency of the production line and increase the production cost.

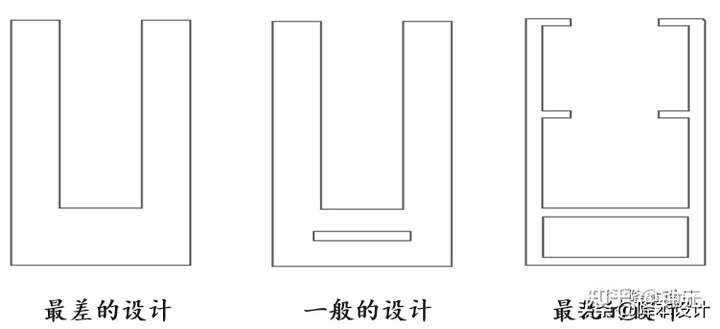

Because plastic extrusion is a continuous process, the strength of the extruded part is low when it is just extruded, and it needs to be supported by air pressure and mandrel to maintain its shape and avoid deformation, while the hollow part cannot provide support, and the complex hollow structure can only be realized by opening the section.

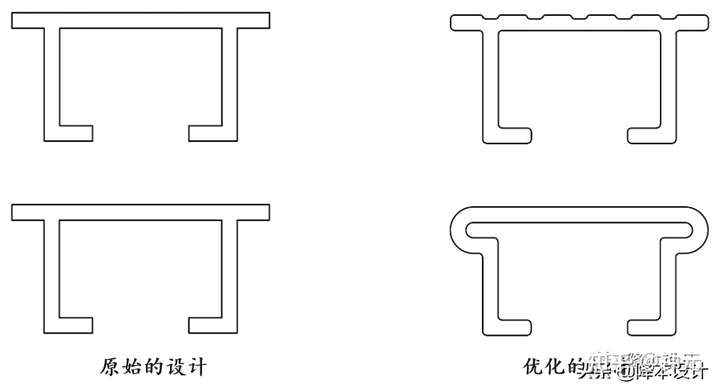

The sharp corner on the extrusion will become a weak point of the extrusion due to stress concentration, which is prone to cracking or failure, and will reduce the impact resistance of the extrusion.

In extruded parts, sharp corners should be avoided as much as possible, and rounded corners should be added at the sharp corners. The fillet radius is equal to the wall thickness of the product, which helps the material flow more smoothly in the extrusion process and reduces the stress at the contour corners.

The sharp corner on the extrusion will become a weak point of the extrusion due to stress concentration, which is prone to cracking or failure, and will reduce the impact resistance of the extrusion.

In extruded parts, sharp corners should be avoided as much as possible, and rounded corners should be added at the sharp corners. The fillet radius is equal to the wall thickness of the product, which helps the material flow more smoothly in the extrusion process and reduces the stress at the contour corners.

At the intersection of multiple walls, areas with thick wall thickness are usually generated, so it is easy to produce shrinkage and poor appearance on the outer surface of the extrusion, which is very similar to injection molding.

If the extrusion is an appearance part, the shrinkage can be avoided or covered up by the optimization design shown in the figure below.

Where possible, strict tolerances in the length direction shall be avoided as far as possible. Thermoplastics shrink and expand with temperature, and cutting plastic extrusions to critical lengths may unnecessarily increase costs.

In general, the tolerance is + / – 5 mm on 1000 mm long extrusions. Of course, the tolerance accuracy is related to the length. The shorter the length, the higher the accuracy can be achieved.

Where possible, strict tolerances in the length direction shall be avoided as far as possible. Thermoplastics shrink and expand with temperature, and cutting plastic extrusions to critical lengths may unnecessarily increase costs.

In general, the tolerance is + / – 5 mm on 1000 mm long extrusions. Of course, the tolerance accuracy is related to the length. The shorter the length, the higher the accuracy can be achieved.

What factors affect the shrinkage of engineering modified plastics PP, PA and PVC? What factors affect the shrinkage of engineering modified plastics PP, PA and PVC?

Previous

What harm does inferior LED lamps do to us?

Next