Building Panel Polycarbonate Profiles: The Future-Proof Solution for Modern Architecture and Industry

Introduction: Redefining Structural Efficiency with Polycarbonate Profiles

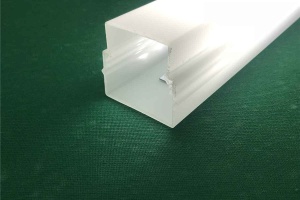

Polycarbonate profiles represent a paradigm shift in engineering materials, combining exceptional strength, optical clarity, and extreme environmental resilience into customizable structural components. Extruded from UV-stabilized polycarbonate, these profiles—available in U, T, H, and bespoke shapes—support diverse sectors from skyscraper facades to aerospace systems. With global construction embracing lightweight, sustainable materials (polycarbonate weighs 1/6 of glass and 1/3 of acrylic), these profiles are revolutionizing how architects and engineers balance performance, aesthetics, and cost.

Core Properties: Engineering Excellence in Every Extrusion

- Material Superiority:

- UV & Weather Resistance: Co-extruded UV layers prevent yellowing, maintaining ≤8% yellowness shift over 10 years.

- Thermal Resilience: Withstands -40°C to 120°C, ideal for desert solar farms or arctic infrastructure.

- Mechanical Strength: 250x more impact-resistant than glass, absorbing extreme forces without cracking.

- Optical & Electrical Performance:

- Light Transmission: Up to 95% clarity in transparent profiles; semi-clear/opal variants offer 85–92% diffusion for glare-free lighting.

- Electrical Insulation: Critical for LED housings, EV components, and high-voltage enclosures.

- Sustainability Edge:

- Lightweight design reduces structural support needs, slashing steel/cement use by 20–30%.

100% recyclable, aligning with EU Circular Economy mandates.

- Lightweight design reduces structural support needs, slashing steel/cement use by 20–30%.

Industry Applications: Solving Real-World Challenges

1. Architectural Facades & Roofing

- Challenge: Glass skylights in warehouses risk shattering and heat loss.

- Solution: U-shaped polycarbonate profiles with 7-wall plug-pattern design for seamless glazing.

- Results:

- 30% better thermal insulation vs. single-pane glass.

- Self-cleaning surfaces cut maintenance costs by 40%.

2. Automotive & Aerospace

- Challenge: Metal components increase EV weight, reducing battery range.

- Solution: T-profile battery trays (custom-cut to 10m lengths) replacing aluminum.

- Results:

- 50% weight reduction, extending range by 15%.

- Flame-retardant (UL94 V-0) protection for battery modules.

3. LED Lighting Systems

- Challenge: Acrylic diffusers yellow under UV, dimming output.

- Solution: Opal polycarbonate extrusion with prismatic light diffusion (92% haze).

- Results:

- 80,000-hour lifespan in outdoor signage.

- Integrated mounting channels simplify installation.

4. Renewable Energy Infrastructure

- Application: Solar panel mounting frames and wind turbine covers.

- Advantage: UV-resistant profiles outlast steel by 25+ years in desert farms.

Customization & Supply Chain Agility

- Shapes & Sizes: U/T/H profiles; widths 150–400mm; lengths ≤10m.

- Colors: Clear, semi-clear, opal, and solid tones (e.g., bronze for solar glare reduction).

- Packing & Delivery: PE-bagged + carton-boxed; 15–20-day lead time even for complex geometries.

- R&D Innovation: New grades include bio-based PC for carbon-neutral projects.

Market Trends Driving Adoption

- Construction Boom: Global demand surges as polycarbonate panels cut building energy use by 30%. China dominates 33% of market consumption.

- EV Revolution: Lightweighting mandates propel PC profiles in battery/body components.

- Circular Economy: 72% of EU architects specify recyclable materials like PC.

Why Choose Polycarbonate Profiles?

| Factor | Traditional Materials | Polycarbonate Profiles |

|---|---|---|

| Weight | Heavy (glass/steel) | 1/6 of glass |

| Installation | Crane-dependent | DIY-friendly |

| Lifespan | 10–15 years | 25+ years |

| ROI | High maintenance | 40% lower lifecycle cost |

Conclusion: Building Smarter, Lighter, and Greener

Polycarbonate profiles are more than components—they are enablers of next-gen design. From Shanghai Tower’s energy-efficient curtain walls to Tesla’s lightweight EV systems, this material merges uncompromising performance with ecological responsibility. As industries prioritize resilience and sustainability, polycarbonate profiles stand as the cornerstone of innovation.

Partner with Us: Leverage our 20-year extrusion expertise and in-house mold design. Submit your blueprint for a free feasibility analysis—transform concepts into corrosion-proof, future-ready structures.