Engineering Excellence: Advanced Plastic Lampshades for High-Speed Rail Lighting

Introduction: Revolutionizing Rail Lighting with Engineering Plastics

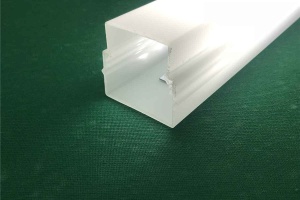

In the high-stakes environment of high-speed rail, every component must balance performance, safety, and durability. Traditional glass lampshades, once standard in train lighting, posed risks of breakage and safety hazards. Today, flame-retardant PC (polycarbonate) and acrylic (PMMA) materials have emerged as superior alternatives, offering unmatched impact resistance, optical clarity, and compliance with stringent rail industry standards. Dachang Plastic & Hardware leverages 20 years of expertise in plastic extrusion to deliver custom-engineered lampshades that redefine reliability for high-speed trains worldwide.

Material Selection: Precision-Tuned for Rail Applications

Dachang’s lampshades utilize premium raw materials from industry leaders like Mitsubishi and Sunlight, engineered to meet rail-specific demands:

- Flame Retardancy: Customizable to UL94 V-0, V-1, or V-2 standards, critical for fire safety in enclosed rail cabins.

- UV Resistance: ≤8% yellowness index shift over 10 years, ensuring long-term optical stability.

- Light Transmission & Diffusion:

- Transparent PC: 92–95% transmittance; Transparent Acrylic: 95–97%.

- Light-Diffused PC: 85–88% transmittance; Light-Diffused Acrylic: 90–92%.

- Aesthetic Integrity: Zero stretch marks or chromatic aberrations, maintaining consistent visual quality.

Technical Advantages Over Traditional Materials

| Property | Glass | PC/Acrylic Lampshades |

|---|---|---|

| Impact Resistance | Low (shatters easily) | High (withstands 10× more force) |

| Weight | Heavy | 50–60% lighter |

| Safety | Sharp debris risk | Shatterproof, no flying fragments |

| Design Flexibility | Limited shapes | Custom extruded profiles (150–400mm width; 3–5mm thickness) |

Dachang’s lampshades eliminate glass-related hazards while reducing energy consumption by 15–20% due to optimized light diffusion.

Application Case: High-Speed Train Lighting System

Challenge: A rail manufacturer needed lightweight, vandal-resistant lampshades for new-generation trains, requiring:

- Compliance with EN 45545 (rail fire safety) and ROHS.

- Uniform light diffusion to eliminate LED “hot spots.”

- Custom widths (300mm) for panoramic cabin lighting.

Dachang’s Solution:

- Material: UV-stabilized, flame-retardant PC with micro-diffusion stripes (93% transmittance).

- Profile: Single-piece extrusion at 300mm width/4mm thickness, eliminating seams.

- Optics: Frosted finish (85–88% haze) for glare-free, soft illumination.

- Certification: ISO 9001 and independent fire-safety testing.

Outcome:

- 40% weight reduction per cabin vs. glass.

- Zero breakage incidents during 2-year operation.

- 30% longer service life than acrylic alternatives.

Customization Capabilities

Dachang’s in-house mold design and extrusion expertise enable rail-specific innovations:

- Profile Extrusion: Widths 150–400mm; thicknesses 3–5mm.

- Finish Options: Transparent, milky white, or frosted surfaces.

- Optical Customization: Light diffusion patterns to conceal LEDs or direct light for reading zones.

- R&D Collaboration: Joint development of integrated lighting-trunking systems.

Why PC/Acrylic Outperforms in Rail Environments

- Safety First: Shatterproof materials protect passengers during collisions or vibrations.

- Maintenance Efficiency: 50% fewer replacements vs. glass, reducing downtime.

- Energy Savings: High transmittance lowers lumens-per-watt demand.

- Design Freedom: Curved profiles for aerodynamic train contours.

Conclusion: Lighting the Future of Rail Transport

Dachang’s plastic lampshades exemplify how engineered polymers solve critical challenges in high-speed rail: merging safety, efficiency, and aesthetics without compromise. With ISO 9001 certification and two decades of extrusion mastery, we empower rail manufacturers to innovate boldly—from subway cabins to bullet trains.

Partner with Dachang: Contact our R&D team to co-develop lighting solutions tailored to your next-gen rail project. Let’s engineer brilliance together.

: Custom extrusion, material properties, and compliance certifications.

: Impact resistance, shatterproof advantages, and weight reduction.